Capabilities That Make a Difference

Mid-Point’s efficient and accurate workflow optimizes interaction between the programmer, program software, and our skilled machinists to produce custom pieces delivered on time. We are proud to offer a wealth of machining options to support your needs, from executing simple designs to the most complex specifications.

At Mid-Point, our customers benefit from our high level of service and reliable production process, closing the gap from where they are, to where they want to be. That’s the Mid-Point Advantage.

Mid-Point has the equipment, knowledge, and experience to meet your exact specifications – within budget and on time. Check out our Machine and Parts Galleries to see the extent of our capabilities

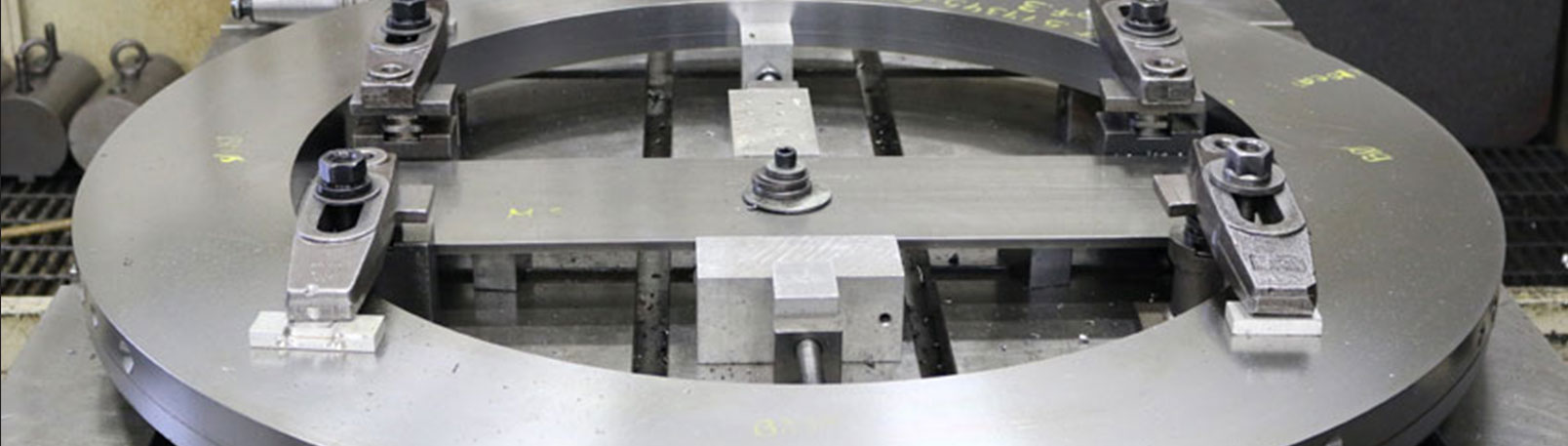

Our vertical and horizontal CNC machining centers are capable of machining from 1/2″ to 120″, offering solutions with fewer steps and reduced cost. Our precision machined components can meet the tightest tolerances of +/- 0.001″ or less.

At Mid-Point, we are very proud of our lathe capabilities including large parts up to 79″ diameters. Consistently producing large parts with precision and care is not an easy task, yet we routinely machine intricate parts that meet our customer’s specifications with tolerances within +/- 0.001″.

Large parts even though they are large demand the same exacting specifications as smaller pieces. We consistently produce large parts within your precision tolerances of +/- 0.001″ and sometimes less.

Many machine shops won’t assemble the parts before they head out the door. But we routinely complete projects with a variety of assembly requirements before shipping. It ensures that all components fit or function as specified. It also helps streamline the customer’s installation upon delivery. Let us know if we can provide this service on your next order.

Mid-Point offers simple welding services to our customers including MIG welding with a variety of materials in-house. When a project requires more involved welding, we outsource to one of our reliable, local fabricators.

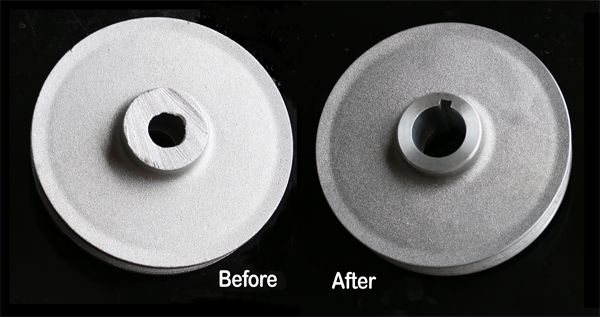

Many parts today need coatings for protection from heat, friction, and caustic environments. Count on Mid-Point to provide a complete turnkey service including the necessary finishes to complete your project. We work with trusted third-party vendors to provide upfront and finishing services that involve heat treating, powder coating, anodizing, and flame cutting, just to name a few. We work with the most common coatings as well as more unique ones.